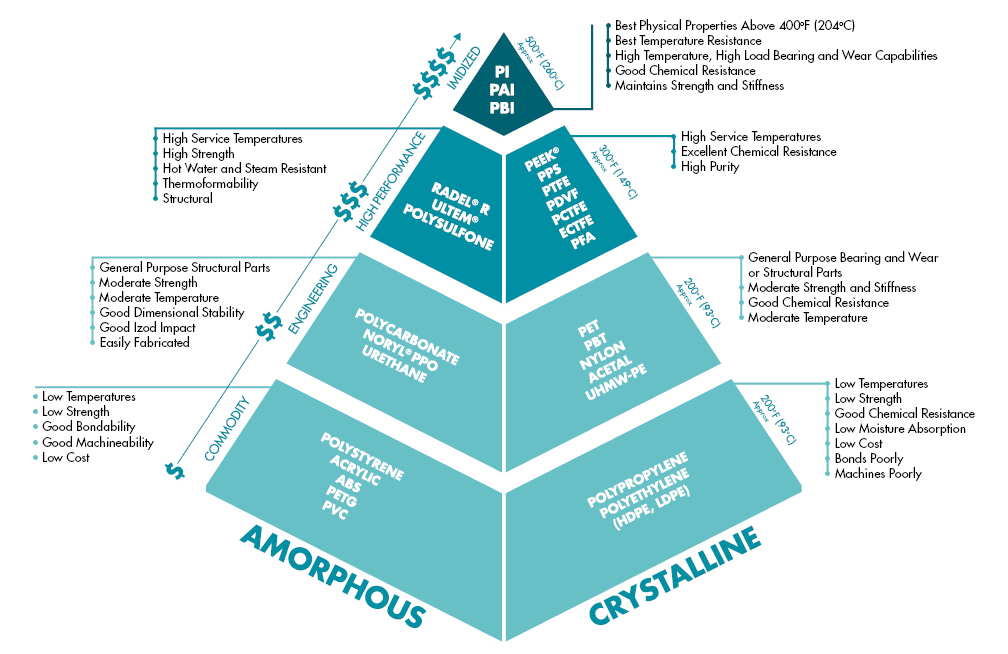

Plastic Material Selection Guide

The plastics pyramid below is an at-a-glance plastic material selection guide. Every application has unique material characteristic requirements for temperature, strength, cost and more. We use the broadest range of injection molding plastic resins, including commodity, engineering and high-performance grades such as Torlon, PEEK, Polysulfone and Polyphenylene Sulfide. Diversified Plastics, Inc. is here to help you select the right plastic for your application.

Amorphous Key Characteristics

High temperature, cost and strength; good stiffness; hot water and steam resistance

- Polyetherimide (PEI) ULTEM®

- Polyphenylsulfone (PPSU) RADEL R®

- Polysulfone

Semi-Crystalline Key Characteristics

High temperature, cost and strength; good chemical resistance; electrical properties

- Polyetheretherketone (PEEK)

- Polyphenylene Sulfide (PPS)

- Polytetrafluoroethylene (PTFE)

- Polyvinylidene Fluoride (PVDF)

- Polychlorotrifluoroethylene (PCTFE)

- Ethylene-Chlorotrifluoroethylene (ECTFE)

- Perfluoroalkoxy (PFA)

Amorphous Key Characteristics

Moderate cost; moderate temperature resistance; moderate strength; good to excellent impact resistance

- Polyurethane (TPU)

- Polyphenylene Oxide (Mod PPO) NORYL®

- Thermoplastic Polyurethane (TPU)

Semi-Crystalline Key Characteristics

Moderate cost; moderate temperature resistance; moderate strength

- Polyethylene Terephthalate (PET)

- Polybutylene Terephthalate (PBT)

- Polyamide (PA) NYLON

- Polyoxymethylene (POM) Acetal

- High Temperature, Ultra-High Molecular Weight Polyethylene (UHMW-PE)

Amorphous Key Characteristics

Low cost; low temperature resistance; low strength

- Polystyrene (PS)

- Acrylic (PMMA)

- Acrylonitrile Butadiene Styrene (ABS)

- Polyethylene Terephthalate Glycol (PETG)

- Polyvinyl Chloride (PVC)

Semi-Crystalline Key Characteristics

Low cost; low temperature resistance; low strength

- Polypropylene (PP)

- High Density Polyethylene (HDPE)

- Low Density Polyethylene (LDPE)